Transmission Case Identification and Interchange

The TH400 has found its way into various vehicle, chassis and engine combinations over the years. This means the transmission cases were cast with numerous transmission to engine mounting flange configurations. The following information will center around the most commonly encountered engine mounting flange configurations which are separated into two groups. The first group is comprised of transmission cases designed to fit Buick, Cadillac, Oldsmobile and Pontiac engines and is referred to as the BCOP casting. The second group is comprised of transmission cases designed to fit Chevrolet engines and is referred to as the Chevrolet casting. There are design features which are both common and unique to each casting group. Because of this, similarities between both groups will be covered first, follow by the features unique to each group.

All 1965 thru 1974 transmission cases were cast and machined to accept the eight-bolt oil pump assembly. The casting received 18 center support/intermediate clutch backing plate lugs, and steel vent tube. See Figure 13-. Note the extra material at the 7:00 position of the pump mounting flange with the eight-bolt case in Figure compared to the six-bolt case in Figure.

For the 1975 model year, two of the oil pump mounting bolts previously fit to the transmission case at the 1:00 and 7:00 positions were deleted, along with their thru holes in the oil pump body casting. With some cases, the two unused bolt hole bosses were completely removed from the casting. With others, either one or both bolt hole bosses may be present, and when present, may or may not be drilled and tapped. Note the presence of the mounting bolt hole boss at the 1:00 position with the 1976 Buick case shown in Figure 13-. The casting received 17 center support/intermediate clutch backing plate lugs, and plastic vent tube. See Figure 13-. The location of the missing lug varies between the 2:00 and 3:00 position.

The BCOP Transmission Case

Several light-duty and heavy-versions of the BCOP TH400 transmission case were produced from 1965 thru 1985. There were also many “blended” castings which resulted in a case with a combination of features found in both versions. When a BCOP case is referenced in this section as light-duty, the casting is said to include all traits outlined in this section used for comparison with what is said to be a heavy-duty casting. The same can be said for the heavy-duty casting. It is also interesting to note that none of the features of the heavy-duty BCOP case were ever incorporated into any of the Chevrolet castings. The heavy duty BCOP case include several casting benefits that significantly increase the structural rigidity of the component. Note the reinforced bellhousing area of the heavy-duty casting with its increased material in the bellhousing mounting area and cast reinforcement ribs.

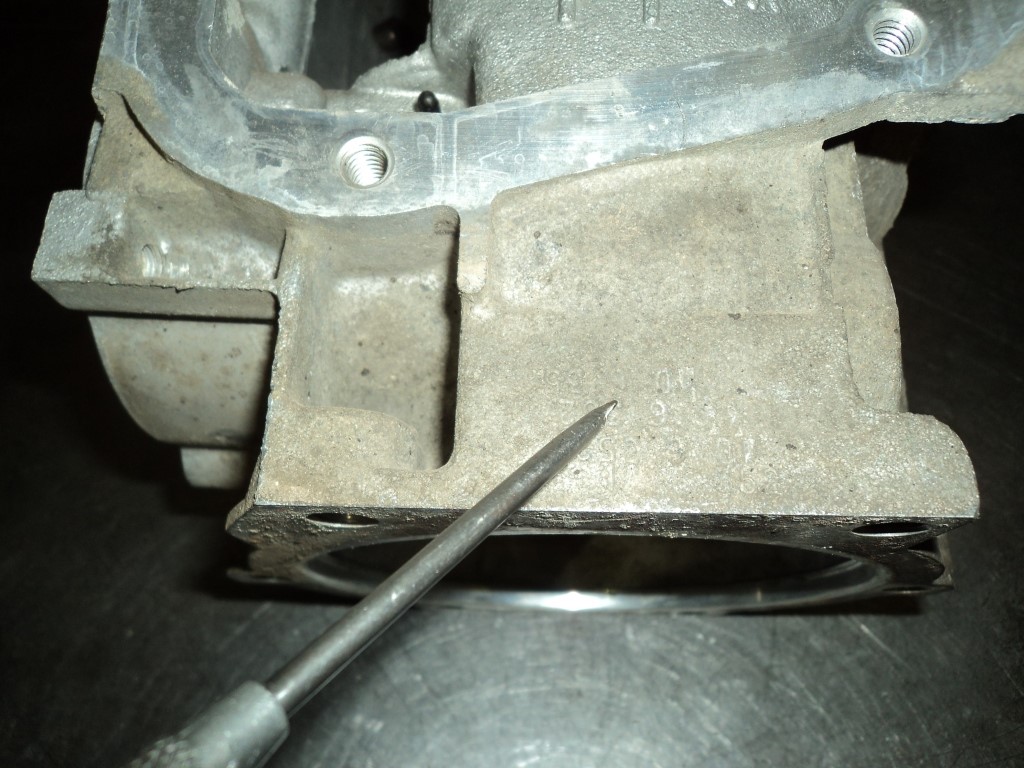

Heavy duty BCOP cases were cast with a significantly thicker oil pan mounting flange. See comparison shown in Figures 13- and 13-.

Heavy duty BCOP cases were also cast with additional reinforcement ribs/webbing which extends from the rear of the valve body mounting flange to the oil pan mounting flange. See comparison shown in Figures 13- and 13-. Worthy of noting is that all production Chevrolet cases, whether standard or HD, cases mimicked the light duty casting traits of the BCOP cases. The reinforcement ribs are also found on all Bentley, Jaguar, and Rolls Royce issue TH400 cases.

For Chevrolet engines, the 1965 to 1976 BCOP transmission case, fitted with an aftermarket bellhousing, will deliver the most rigid foundation for assembling a high performance TH400 with a production transmission case. With high output BCOP engines, the 1965 to 1976 BCOP transmission case is heavily reinforced in the bellhousing area, making the use of an aftermarket bellhousing not necessary for most radical drag racing applications. With the addition of the six bolt hole oil pump assembly in 1975, some, but not all BCOP transmission case casting changes resulted in a much lighter duty casting, similar to the Chevrolet design. These lighter duty castings are recommended for street and strip vehicles up to 750 horsepower.

The use of an aftermarket bellhousing may be necessary to attach a transmission case with the desired design features to the engine in use.

However, when assembling a transmission for competition usage, the heavy duty BCOP case is the preferred foundation. At power levels beyond 750 foot pounds of torque, the use of an aftermarket bellhousing fitted to the case is recommended.

The Chevrolet Transmission Case

The standard Chevrolet TH400 transmission case was produced from 1965 thru 1984 and shares most of its casting traits with those found on the light-duty BCOP versions. For the 1985 model year, the Chevrolet “HD” or Heavy Duty transmission case was introduced for use in light, medium and heavy-duty trucks. Casting revisions resulted in a much cleaner case and included increased material at locations identified by engineers to require reinforcement. These cases are easily identified by increased material in the bellhousing and extension housing areas. Later versions of the case received the “HD” designation cast into the bellhousing area as shown in Figure 13-.

The “HD” case offers increased material in the bellhousing and inspection/converter cover mounting flange area. 2WD models continued to use the four bolt tin inspection cover, while 4WD models were drilled and tapped to accept 6 large mounting bolts and upgraded cast aluminum inspection/converter cover. Steel reinforcement bars then tie the cover to the engine block and transfer case.

HD cases were also cast with a revised extension housing mounting flange area to increase transmission case rigidity to provide additional support for the transfer case in 4WD applications. Additional material was added to the area immediately behind/between the top two mounting hole bosses. Note the comparison between the HD and standard case shown in Figures 13- and 13-.

Additional material was also added to the area immediately behind/between the bottom two mounting hole bosses. Note the comparison between the HD and standard case shown in Figures 13- and 13-.

For most stock suspension street/strip applications with engines producing up to 500-foot pounds of torque, the standard Chevrolet casting should be adequate. At power levels beyond 500-foot pounds of torque, the use of the Chevrolet “HD” transmission case, or the heavy-duty BCOP case fit with an aftermarket bellhousing should be considered.

With the improvements made to the HD transmission case, its use behind a 1000 plus horsepower in vehicle with a properly set up suspension is becoming increasingly common. When assembling a TH400 for drag race or off-road usage behind a high-powered/high torque Chevrolet engine, the heavy-duty BCOP case fit with an aftermarket bellhousing will furnish the most rigid foundation obtainable with an OEM transmission case.